The construction industry constantly seeks materials that offer greater strength, longevity, and environmental responsibility. Among these, blast furnace cement stands out. This material, also known internationally as GGBS (Ground Granulated Blast Furnace Slag) or GGBFS, is not a new invention. Its use, however, is experiencing a significant surge. This growth is driven by a deeper understanding of its technical benefits and the global push for greener building practices. Forward-thinking suppliers like Golden Fortune are at the forefront, providing high-quality materials that meet these modern demands.

Understanding Blast Furnace Cement and Its Production

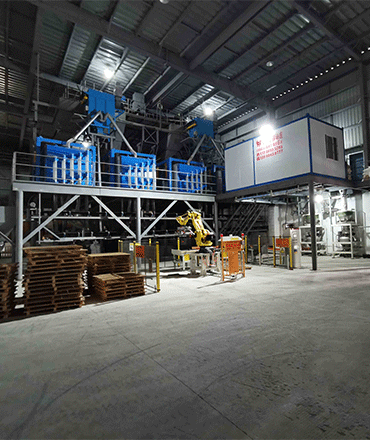

Blast furnace cement is not a standalone product. It is a composite cement created by blending Portland cement clinker with a significant proportion of ground granulated blast furnace slag (GGBS). The slag itself is a by-product of the iron-making process. When molten iron slag is rapidly quenched with water, it forms granular particles with latent hydraulic properties. These granules are then dried and ground to a fine powder, similar to cement. When mixed with Portland cement and water, it undergoes a secondary hydration reaction, leading to superior long-term properties. This process transforms an industrial by-product into a valuable construction resource.

The Core Advantages of Using Blast Furnace Cement

The integration of GGBS into concrete mixes brings a multifaceted improvement. Here are the primary benefits that are changing how engineers and architects specify materials.

1. Enhanced Durability and Long-Term Strength

While early strength development might be slightly slower, the long-term strength of blast furnace cement concrete often surpasses that of ordinary Portland cement (OPC) concrete. More importantly, it dramatically improves durability. The refined pore structure reduces permeability, making the concrete far more resistant to aggressive agents.

Sulfate Attack: Highly resistant to sulfate ions found in seawater and soils.

Chloride Ingress: Protects reinforcing steel from corrosion, extending the life of marine structures and bridges.

Alkali-Silica Reaction (ASR): Effectively suppresses this destructive reaction that can cause cracking.

2. Superior Environmental Profile

This is one of the most compelling reasons for its growing adoption. Using GGBS directly reduces the carbon footprint of concrete.

Reduced CO2 Emissions: Producing GGBS requires less than 20% of the energy needed for Portland cement, leading to a substantial cut in CO2 emissions.

Industrial By-product Utilization: It gives a valuable second life to slag, reducing landfill waste.

Resource Efficiency: It conserves natural limestone and other raw materials required for clinker production.

3. Improved Workability and Aesthetic Finish

Concrete mixes containing blast furnace cement often exhibit better workability and cohesion. The finer particles of quality GGBS, such as that supplied by Golden Fortune, can lead to a smoother, more plastic mix. This results in easier placement and a superior surface finish. Furthermore, the concrete typically has a lighter, more consistent color, which is advantageous for architectural applications where appearance matters.

4. Lower Heat of Hydration

Mass concrete pours, like those in dams, thick foundations, or large piers, face a major challenge: thermal cracking. The hydration of cement generates heat. Blast furnace cement generates heat at a much slower and lower rate. This characteristic minimizes the risk of damaging internal temperature differentials and cracking, improving the integrity and water-tightness of large structural elements.

Technical Performance in Specialized Applications

The properties of blast furnace cement make it the material of choice for challenging environments. Its resistance to chemical attack is crucial for wastewater treatment plants, foundations in aggressive soils, and coastal defense structures. The reduced permeability is vital for water-retaining structures like reservoirs and tanks. In major infrastructure projects, from tunnels to high-rise buildings, its combination of durability and sustainability is increasingly specified. Partners like Golden Fortune provide the consistent, high-performance material needed for these critical projects.

Economic Considerations and Life-Cycle Cost

While the initial material cost can be comparable or situation-dependent, the true economic benefit of blast furnace cement lies in life-cycle costing. Structures built with it require less maintenance and repair over decades of service. The extended service life before major refurbishment translates into significant long-term savings for asset owners, making it a smart economic choice, not just a technical or environmental one.

Frequently Asked Questions (FAQs) About Blast Furnace Cement

Q1: What is the typical replacement level of GGBS in blast furnace cement?

A1: Replacement levels commonly range from 30% to 70% of the Portland cement content. For general construction, 50% is a standard figure. In marine or aggressive environments, levels of 70% or higher are often used to maximize durability.

Q2: Does concrete with blast furnace cement take longer to set?

A2: Yes, setting times can be slightly extended, especially in cooler weather. This can be managed effectively with proper mix design, curing, and, if necessary, the use of set accelerators. The extended workability time can be beneficial for large pours.

Q3: Is blast furnace cement suitable for all concrete applications?

A3: It is highly versatile but requires careful consideration for early-strength critical applications (e.g., pre-cast elements with rapid turnaround) or in cold weather concreting. In these cases, lower replacement ratios or specific admixtures are used.

Q4: How does it contribute to sustainable or green building certifications?

A4: The use of GGBS directly contributes to credits in major green building standards like LEED, BREEAM, and Green Mark. Its role in reducing embodied carbon and utilizing recycled content is highly valued in these rating systems.

Q5: Can blast furnace cement be used with supplementary cementitious materials (SCMs) like fly ash?

A5: Absolutely. Ternary blends combining Portland cement, GGBS, and fly ash (or silica fume) are increasingly common. These blends optimize performance, tailoring properties like early strength, ultimate durability, and environmental impact for specific project needs.

The Future is Built with Blast Furnace Cement

The evidence is clear. Blast furnace cement offers a powerful solution to the dual challenges of building durable infrastructure and reducing the environmental impact of construction. Its proven benefits in strength, chemical resistance, and thermal behavior make it a technically superior choice for a wide range of applications. As the industry moves towards a more sustainable future, the role of GGBS will only expand. Choosing a reliable, quality-focused supplier is essential to realizing these benefits. For projects that demand performance and responsibility, materials from companies like Golden Fortune provide a solid foundation for the future.