Concrete shrinkage is a persistent challenge for engineers and contractors. It leads to cracks, compromises structural integrity, and reduces the lifespan of builds. A **shrinkage compensating admixture** offers a proactive solution. By integrating materials like GGBS/GGBFS with these advanced admixtures, we can significantly enhance performance. Brands like Golden Fortune have developed formulations that address these issues effectively, providing more reliable and durable concrete structures from the ground up.

Understanding How Shrinkage Compensating Admixtures Work

These admixtures do more than just reduce water content. They are engineered to create controlled expansion during the early hardening phase. This expansion counteracts the tensile stresses that cause shrinkage cracks. The chemistry involves reactive compounds that generate expansive products within the concrete matrix.

The timing of the expansion is critical. It must synchronize with the concrete's setting and strength gain. When used alongside supplementary cementitious materials like GGBS, the effect is often improved. GGBS contributes to long-term strength and refines the pore structure, creating a more receptive environment for the **shrinkage compensating admixture** to perform consistently.

Induce controlled expansion during early curing.

Counteract tensile stresses from drying shrinkage.

Generate stable expansive products within the paste.

Synergize with GGBS for enhanced microstructure.

Enhancing Durability with Reduced Cracking

Cracks are the primary entry point for water, chlorides, and sulfates. By minimizing shrinkage cracking, these admixtures directly boost concrete's resistance to aggressive environments. This is vital for infrastructure like bridges, parking decks, and water treatment plants. The result is a longer service life with lower maintenance costs.

Combining a **shrinkage compensating admixture** with GGBS takes durability further. GGBS lowers permeability and improves chemical resistance. The admixture ensures the dense matrix formed by GGBS remains intact and uncracked. This dual approach is a smart strategy for severe exposure conditions.

Improving Structural Integrity and Joint Spacing

Less shrinkage means less internal stress on the concrete element. This maintains the intended load-bearing capacity and reduces long-term deflection. Designers can also specify longer distances between control joints. This leads to cleaner aesthetics and reduced construction complexity on large slabs and walls.

For industrial floors or warehouse slabs, this is a major advantage. Fewer joints mean smoother surfaces for equipment traffic and lower installation costs. Products from Golden Fortune are formulated to provide this reliable, predictable performance, giving contractors greater confidence in their schedules.

Synergy with GGBS/GGBFS in Modern Mix Designs

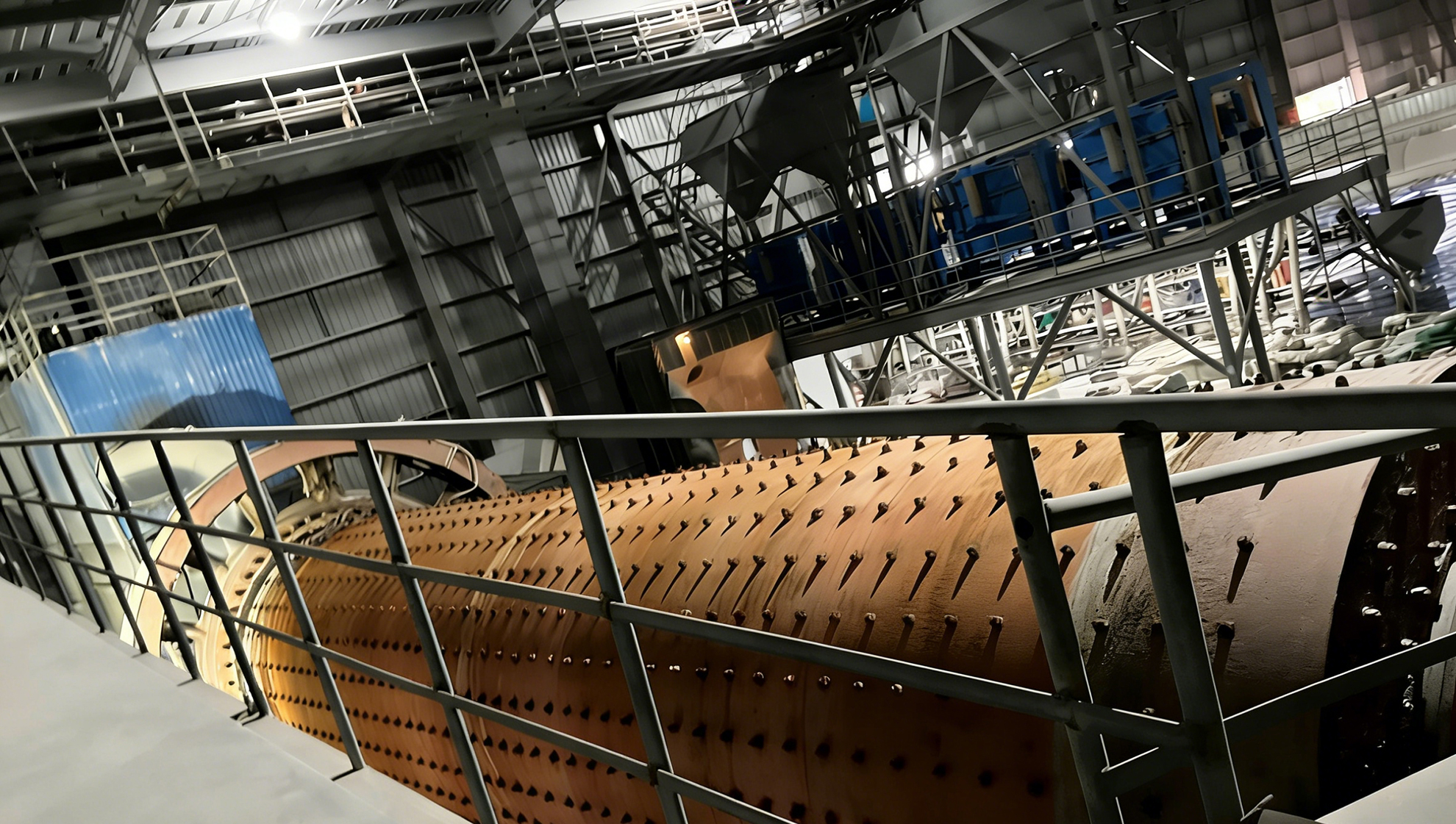

Ground Granulated Blast-furnace Slag (GGBS/GGBFS) is a staple in sustainable, high-performance concrete. It reduces the carbon footprint and enhances long-term strength. However, its slower early strength gain and specific curing needs require careful planning.

A well-chosen **shrinkage compensating admixture** complements GGBS perfectly. It manages early-age volume change while the GGBS contributes to later-age durability. This combination produces concrete that is not only crack-resistant but also highly durable and sustainable. It represents a holistic approach to modern concrete technology.

GGBS reduces heat and improves sulfate resistance.

Admixtures manage early-age shrinkage during GGBS's slower reaction.

The combination yields a dense, impermeable, and crack-free matrix.

Ideal for projects targeting sustainability certifications.

Application Considerations and Best Practices

Successful use requires attention to detail. Batching sequence, mixing time, and curing are all important. The admixture must be dispersed evenly throughout the mix. Immediate and proper curing is non-negotiable to support the expansion mechanism and ensure strength development.

Consultation with technical experts is recommended. Suppliers like Golden Fortune provide detailed guidelines for their products. They can help tailor the dosage and mix design for specific project requirements, whether using high volumes of GGBS or other supplementary materials.

Conclusion: A Strategic Choice for Long-Term Performance

Choosing to include a **shrinkage compensating admixture** in a concrete specification is a decision that pays off over decades. It moves the focus from repairing cracks to preventing them. When integrated with the benefits of GGBS, it creates a robust material capable of withstanding time and the elements. For engineers seeking reliability, specifying proven solutions from industry leaders like Golden Fortune provides an added layer of assurance for the longevity of their structures.

Frequently Asked Questions (FAQs)

Q1: Can a shrinkage compensating admixture replace control joints entirely?

A1: No, it cannot completely replace control joints. These admixtures significantly reduce shrinkage stress and allow for greater distances between joints, but joints are still necessary to accommodate other movements like thermal expansion and contraction. The design and spacing should follow engineering guidelines.

Q2: How does a shrinkage compensating admixture interact with other common admixtures, like water reducers?

A2: They are generally compatible. In fact, they are often used together. Mid-range or high-range water reducers help achieve a workable mix with lower water content, which further reduces drying shrinkage. The key is to follow the manufacturer's dosing and sequencing advice. Golden Fortune provides compatibility data for its product lines.

Q3: Is there a special curing requirement for concrete containing these admixtures?

A3: Yes, proper and immediate curing is even more critical. The expansive reactions require moisture to proceed correctly and generate the intended benefits. Curing methods like wet burlap, membranes, or sprays should begin as soon as possible after finishing to prevent premature moisture loss.

Q4: Are these admixtures suitable for use with high-volume GGBS mixes (e.g., 50%+ replacement)?

A4: Yes, they are particularly suitable. High-volume GGBS mixes have different shrinkage and hardening characteristics. A shrinkage compensating admixture helps manage early-age volume change during the slower strength gain period of GGBS, making the combination a powerful duo for durable, low-crack concrete.

Q5: What is the main cost-benefit analysis for using these admixtures?

A5: The initial cost is offset by multiple long-term savings: reduced risk of cracking and repair, less joint maintenance, extended structural service life, and lower lifecycle costs. For owners, this means better asset preservation. The value is clear in critical infrastructure and high-traffic industrial floors.