Delivering consistent, high-quality concrete from the plant to the site is the core challenge of modern construction. The solution lies in precise formulations that include specialized chemical additives. **Ready mix concrete admixtures** are integral to this process, transforming standard mixes into customizable materials for specific project needs. Their use becomes even more critical when incorporating sustainable materials like Ground Granulated Blast-furnace Slag (GGBS/GGBFS). Manufacturers like Golden Fortune develop these admixtures to help producers meet the growing demands for performance, durability, and efficiency in a competitive market.

The Essential Types of Ready Mix Concrete Admixtures

Not all admixtures serve the same purpose. Each type addresses a specific challenge during mixing, transportation, placement, or curing. Knowing which one to use is fundamental for batching plant operators and engineers.

The most common categories include water reducers, retarders, accelerators, and air-entraining agents. Superplasticizers, a high-range water reducer, are particularly vital for achieving flowable concrete with low water content. For mixes designed with GGBS, specific admixtures help manage setting times and early strength development. The right combination of **ready mix concrete admixtures** ensures the concrete arrives on site in perfect condition.

Water Reducers: Lower the water demand for a given slump, increasing strength.

Retarders: Slow the setting time, crucial for long hauls or hot weather.

Accelerators: Speed up setting and early strength gain, ideal for cold weather.

Air-Entrainers: Introduce microscopic air bubbles for freeze-thaw resistance.

Superplasticizers: Enable high-slump, self-consolidating concrete without segregation.

Key Benefits for Concrete Producers and Contractors

These chemical additions offer tangible advantages that impact the entire construction process. For producers, they allow for more flexible and reliable batching schedules. They can optimize cement content without sacrificing performance, which helps control material costs.

For contractors, the benefits are seen on site. Concrete is easier to place, finish, and manage. It meets strength specifications reliably and develops the necessary durability for the structure's intended life. Using advanced **ready mix concrete admixtures** minimizes callbacks for repairs and enhances the overall quality of the finished build. Solutions from providers like Golden Fortune are engineered to deliver these consistent results batch after batch.

Synergy with GGBS/GGBFS in Sustainable Mix Designs

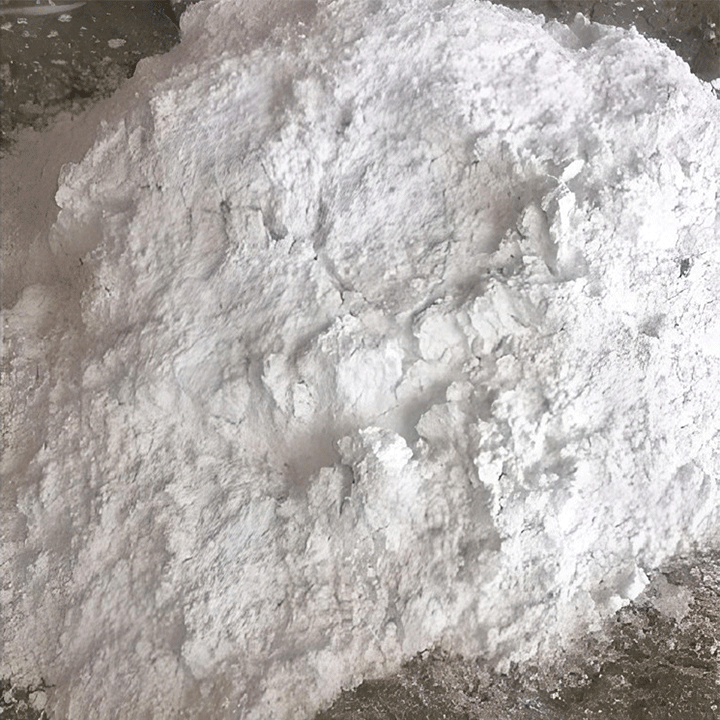

The construction industry is actively reducing its carbon footprint, and GGBS is a key component in this shift. As a supplementary cementitious material, it significantly lowers the clinker factor in concrete. However, its slower reaction rate presents specific challenges for ready-mix production.

This is where tailored admixtures prove their worth. They compensate for the slower early strength development of GGBS mixes when needed. They also improve the workability of these sometimes sticky mixes, ensuring they remain pumpable and placable. The strategic use of **ready mix concrete admixtures** unlocks the full potential of GGBS, resulting in concrete that is not only greener but also highly durable with excellent long-term strength and permeability characteristics.

Optimizing Workability and Placeability on Site

Concrete must remain workable from the drum through to final placement. Admixtures provide crucial control over this critical period. Retarders are essential for preventing stiffening during traffic delays or for large pours. Superplasticizers allow for easier placement in tight, heavily reinforced formwork.

This control reduces labor effort and improves surface finish quality. It allows for more efficient scheduling of crews and equipment. The goal is to deliver concrete that performs predictably for the finishing team, eliminating guesswork and waste.

Enhancing Durability and Long-Term Service Life

The true test of concrete happens years after construction. Admixtures play a direct role in extending a structure's lifespan. Air-entraining agents protect against scaling and cracking in freeze-thaw cycles. Corrosion-inhibiting admixtures protect steel reinforcement.

When used in concert with GGBS, which densifies the concrete matrix and improves chemical resistance, the durability benefits multiply. This combination is powerful for infrastructure exposed to harsh environments, such as marine settings or de-icing salts. Specifying the correct **ready mix concrete admixtures** is an investment in reduced maintenance and greater asset longevity.

Best Practices for Selection and Dosing

Successful application requires more than just adding a liquid to the mix. The choice and dosage depend on numerous factors. Cement type, mix proportions, ambient temperature, and the use of other materials like GGBS or fly ash all influence the outcome.

Collaboration with the admixture supplier is essential. Reputable companies like Golden Fortune offer technical support to conduct trial mixes and determine the optimal dosage for local materials and conditions. This step prevents issues like over-retardation or unexpected setting behavior, ensuring plant operations run smoothly.

Always conduct site-specific trial batches.

Consider the full mix design, including all SCMs like GGBS.

Account for ambient temperature and expected transport time.

Use automated, calibrated dispensing systems for consistency.

Train batching plant personnel on proper addition sequences.

Conclusion: A Critical Tool for Modern Concrete Quality

**Ready mix concrete admixtures** are far from optional extras; they are fundamental components of high-performance concrete production. They provide the necessary control to navigate variable site conditions, material properties, and performance specifications. By enabling the effective use of GGBS, they also support the industry's sustainable development goals. For producers aiming to deliver superior, reliable concrete, partnering with a knowledgeable admixture supplier such as Golden Fortune is a strategic step toward achieving greater efficiency, consistency, and customer satisfaction in every cubic meter delivered.

Frequently Asked Questions (FAQs)

Q1: Can I use multiple types of admixtures in a single ready-mix load?

A1: Yes, it is common to use two or more admixtures to achieve combined effects, such as a water-reducer and a retarder. This is called "combination dosing." However, compatibility is crucial. The admixtures must be tested together in the specific mix design to avoid adverse interactions. Suppliers formulate products to be compatible, but preliminary trials are always recommended.

Q2: How do admixtures affect the final cost of ready-mix concrete?

A2: While they add a direct material cost, admixtures often lead to net savings. By allowing reduced water and cement content, improving workability to lower labor costs, and enhancing durability to cut long-term maintenance, they improve the overall value. The initial investment typically pays off through optimized mix designs and better field performance.

Q3: Are there special considerations for using admixtures with high GGBS content mixes (over 50%)?

A3: Yes. High-GGBS mixes often require adjusted admixture dosages. They may need slightly more water reducer or superplasticizer to achieve target workability due to the finer particles of GGBS. Retarder usage might also need fine-tuning as GGBS can already slow early setting. Close coordination with your admixture provider is key to optimizing these blends.

Q4: What happens if the admixture dosage is accidentally too high or too low?

A4: Incorrect dosage can cause significant problems. Over-dosing a retarder can delay setting for days, while under-dosing might cause rapid stiffening. Over-dosing air-entrainer can severely reduce strength. Precise, automated dosing equipment and strict quality control procedures at the batching plant are essential to prevent these costly errors.

Q5: How do temperature changes affect the performance of ready mix concrete admixtures?

A5: Temperature has a major impact. In hot weather, concrete sets faster, often requiring more retarder. In cold weather, setting slows, and accelerators may be needed. Reputable admixture systems, like those from Golden Fortune, offer seasonal formulations or detailed dosage adjustment charts to help producers compensate for temperature fluctuations effectively.