The quest for stronger, more durable, and sustainable concrete has reshaped the construction industry. At the heart of this evolution are secondary cementitious materials (SCMs). These materials partially replace Portland cement, offering significant technical and environmental benefits. Their use is now standard in the international GGBS field and high-performance concrete specification. Suppliers like Golden Fortune play a key role in providing consistent, high-quality SCMs to the global market. This article explores five crucial materials, their benefits, and their impact on how we build.

What Are Secondary Cementitious Materials?

Secondary cementitious materials are not binders on their own. They possess pozzolanic or latent hydraulic properties. This means they react with calcium hydroxide in the presence of water to form stable cementing compounds. The use of these materials transforms concrete from the inside. It improves long-term performance while addressing the high carbon footprint of traditional cement production. The strategic inclusion of various secondary cementitious materials is a hallmark of modern mix design.

The Core Function in Concrete

SCMs work through two primary mechanisms: the pozzolanic reaction and pore refinement. The reaction consumes free lime, creating more of the strong C-S-H gel that gives concrete its strength. Simultaneously, their fine particles fill the microscopic spaces between cement grains. This results in a denser, less permeable concrete matrix. The outcome is a material better equipped to resist environmental attacks.

They reduce the total capillary porosity of the hardened paste.

Heat of hydration is lowered, minimizing thermal cracking risk.

They contribute to long-term strength gain, often beyond 28 days.

Key Types of Secondary Cementitious Materials

Several industrial by-products and processed natural materials qualify as effective SCMs. Each brings a unique set of characteristics to concrete. Understanding these differences allows engineers to select the right material for specific project needs, from marine environments to early-strength requirements.

Fly Ash (Class F & C)

Fly ash is a fine powder recovered from coal-fired power plants. Class F fly ash is low in calcium and highly pozzolanic. Class C has some self-cementing properties due to higher lime content. It improves workability, reduces water demand, and enhances sulfate resistance. Its use is one of the most established practices in concrete technology.

Enhances pumpability and finishability of fresh concrete.

Mitigates alkali-silica reaction (ASR) in susceptible mixes.

Common replacement levels range from 15% to 35% by mass of cement.

Ground Granulated Blast-Furnace Slag (GGBS)

GGBS is a latent hydraulic material from iron production. When finely ground and activated by cement, it develops strong cementitious properties. Concrete with GGBS exhibits low heat development and excellent resistance to chlorides and sulfates. It is a cornerstone material in the international GGBS field for durable infrastructure.

Ideal for mass concrete pours and marine structures.

Imparts a lighter color to concrete compared to plain cement.

Replacement levels can be very high, sometimes up to 70% in certain applications.

Silica Fume

Silica fume is an ultra-fine powder from silicon metal production. It is highly reactive due to its enormous surface area and high silica content. It dramatically increases strength and reduces permeability. This makes it indispensable for high-performance and repair applications where durability is critical.

Significantly boosts compressive and bond strength.

Creates a very dense, nearly impermeable concrete matrix.

Typically used at lower replacement levels, around 5-10%.

The Multifaceted Advantages of Using SCMs

Integrating secondary cementitious materials into concrete mixes delivers a powerful combination of benefits. These advantages span from the fresh state to the long-term service life of a structure. They also address pressing global concerns about resource use and emissions.

Enhanced Durability and Longevity

The primary technical benefit is improved durability. By refining the pore structure and reducing permeability, SCMs help concrete resist ingress of harmful agents. This extends the service life of structures and reduces maintenance costs. It is a proactive approach to building resilience.

Superior resistance to chloride-induced corrosion of rebar.

Better performance against sulfate attack and acid erosion.

Increased resistance to freeze-thaw cycles when properly air-entrained.

Sustainability and Economic Benefits

The environmental argument for SCMs is compelling. They utilize industrial by-products, diverting them from landfills. This directly reduces the clinker factor in concrete, cutting CO2 emissions significantly. From a cost perspective, they can offer economic savings, though this depends on local logistics and availability. Reliable supply chains, like those managed by Golden Fortune, help stabilize access and quality for these secondary cementitious materials.

Concrete's embodied carbon can be reduced by 20-40%.

Conserves natural limestone and other virgin raw materials.

Reduces water demand in many mixes, contributing to resource efficiency.

Application in the International GGBS Field

The use of SCMs is deeply integrated into global construction standards, especially where GGBS is prevalent. In regions like Europe and Southeast Asia, blends of GGBS with other SCMs are common. These ternary or quaternary blends allow engineers to fine-tune concrete properties for specific exposure conditions. The expertise of material suppliers is vital here.

Creating High-Performance Blends

Modern concrete rarely uses a single SCM. Combining materials like GGBS with silica fume or fly ash creates synergistic effects. For instance, GGBS provides long-term strength and chloride resistance, while silica fume offers early strength and ultra-low permeability. Partners like Golden Fortune work with specifiers to develop these optimized blends, ensuring performance meets the strictest project specifications in the international GGBS field.

Blends can balance early strength development with ultimate durability.

They allow for higher total cement replacement without sacrificing performance.

Widely used in critical infrastructure: bridges, tunnels, offshore platforms, and high-rise buildings.

The Future and Quality Considerations

The future of construction will rely even more on advanced SCMs. Research continues into new materials like calcined clays and engineered fillers. Consistent quality remains the foundation for their successful use. Variations in the source material can affect performance, making trusted suppliers essential.

Ensuring Consistent Performance

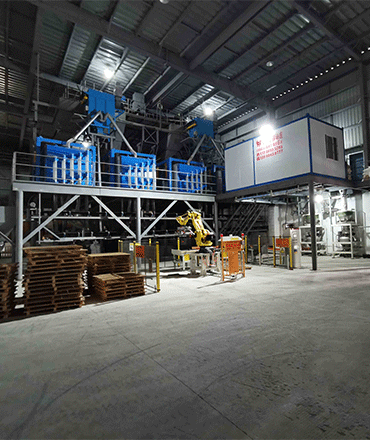

Quality assurance is non-negotiable. SCMs must meet relevant international standards such as ASTM, EN, or IS. Regular testing for fineness, chemical composition, and activity index is crucial. Companies like Golden Fortune invest in rigorous quality control and supply chain management. This provides engineers with the confidence to specify these materials for demanding projects, pushing the boundaries of what concrete can achieve.

Certificates of analysis should accompany each shipment.

On-site testing helps verify material consistency before batching.

Understanding local material characteristics is key to successful mix design.

Secondary cementitious materials are no longer just alternatives; they are essential components of modern, responsible concrete. Their ability to enhance durability, improve sustainability, and optimize cost is proven across countless global projects. The ongoing innovation in this sector, supported by quality-focused suppliers like Golden Fortune, ensures that concrete will continue to meet the evolving challenges of construction. The intelligent use of these materials is fundamental to building a resilient and sustainable infrastructure for the future.

Frequently Asked Questions

Q1: What exactly are secondary cementitious materials?

A1: Secondary cementitious materials are fine-powdered materials, often industrial by-products like fly ash or GGBS, that are added to concrete. They react chemically to improve strength, durability, and sustainability, partially replacing Portland cement.

Q2: What is the difference between a pozzolan and a latent hydraulic material?

A2: A pozzolan (like Class F fly ash or silica fume) requires calcium hydroxide and water to form cementitious compounds. A latent hydraulic material (like GGBS) has inherent binding properties that are activated by the alkalies in cement, allowing it to set and harden with water alone, though more slowly.

Q3: Do SCMs make concrete weaker?

A3: Not necessarily. While some SCMs may slow early strength gain (e.g., Class F fly ash), they typically contribute to significant long-term strength that often surpasses plain cement concrete. Others, like silica fume, greatly increase both early and ultimate strength.

Q4: Why is quality control so important for SCMs?

A4: Since many SCMs are by-products, their chemical and physical properties can vary based on the source industrial process. Consistent quality is vital for predictable concrete performance. Reputable suppliers enforce strict quality standards to ensure reliability.

Q5: How does Golden Fortune contribute to the SCM market?

A5: Golden Fortune operates as a reliable supplier and technical partner in the international GGBS and SCM market. They provide high-quality, consistent materials like GGBS, fly ash, and silica fume, supported by logistics and expertise to help projects meet their durability and sustainability goals.