Concrete Admixture – Silica Fume

Description

Silica fume primarily consists of amorphous (non-crystalline) silicon dioxide. The average particle diameter is 0.08 um; specific surface area is about 4500 m2 /kg; and bulk density is 200 – 250kg/m3. Silica fume has extremely high surface activity with unformed spheroidal silica dioxide particle, the particle size is 1% of cement particle size. It will fill fully into the gaps among cement particles and create gel when reacts with hydrate compound. Golden Fortune dry densified silica fume powder designed to increase concrete compressive and flexural strength, reduce permeability, increase durability and improve hydraulic abrasion/erosion resistance.

- Advantage:

- Reduces permeability

- Enhances durability against aggressive chemical attack

- Improved resistance to abrasion

- Reduces the intrusion of chloride

- Compressive strength increase

Usage

1) High-performance Concrete (HPC) containing silica fume

For highway bridges, parking decks, marine structures and bridge deck overlays which are subjected to constant deterioration caused by rebar corrosion current, abrasion and chemical attack. Silica fume will protect concrete against deicing salts, seawater, road traffic and freeze/thaw cycles. Rebar corrosion activity and concrete deterioration are virtually eliminated, which minimizes maintenance expense.

2) High-strength concrete enhanced with silica fume

This provides architects and engineers with greater design flexibility. Traditionally used in high-rise buildings for the benefit of smaller columns (increasing the usable space) high-strength concrete containing silica fume is often used in precast and prestressed girders allowing longer spans in structural bridge designs.

3) Silica-fume Shotcrete

It delivers greater economy, greater time savings and more efficient use of sprayed concrete. Silica fume produces superior shotcrete for use in rock stabilization; mine tunnel linings; and rehabilitation of deteriorating bridge and marine columns and piles. Greater bonding strength assures outstanding performance of both wet and dry process shotcreting with less rebound loss and thicker applications with each pass of the shotcrete nozzle.

4) Repair Products

Silica fume is used in a variety of cementitious repair products. Mortars or grouts modified with silica fume can be tailored to perform in many different applications—overhead and vertical mortars benefit from silica fume’s ability to increase surface adhesion. Silica fume significantly improves cohesiveness, making it ideal for use in underwater grouts; it decreases permeability in grouts used for post-tensioning applications, and increases resistance to aggressive chemicals.

Chemical Composition

| Items | SiO2 | ZrO2 | Fe2O3 | Al2O3 | Na2O | K2O | TiO2 |

| Content (%) | 75 ~ 95 | 6 ~ 10 | ≤0.4 | ≤0.5 | ≤0.05 | ≤0.02 | ≤0.05 |

Following are three types of silica fume according to different silica dioxide content:

| Grades | Characteristics |

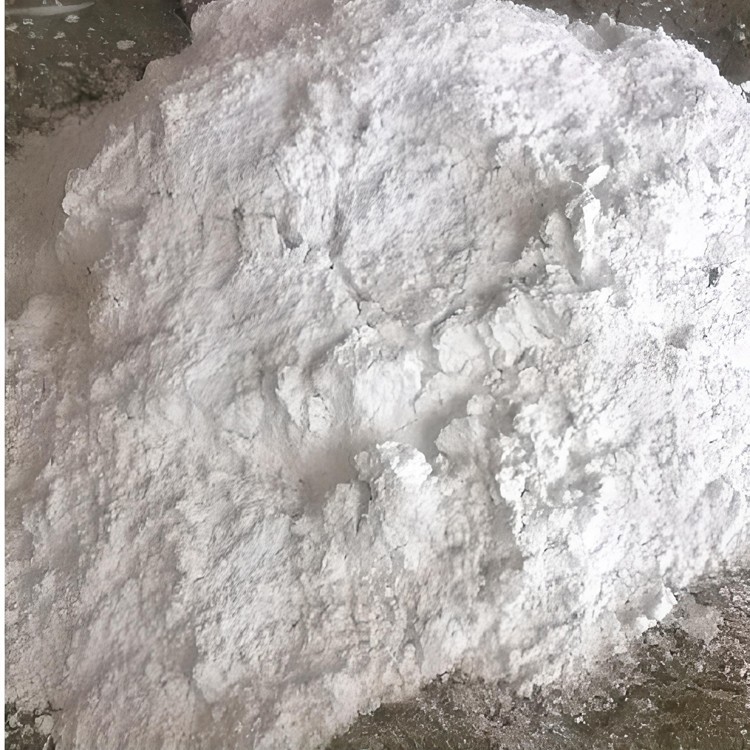

| Super-fined silica fume | SiO2 ≥90%, white powder form, applied in ornamental concrete. |

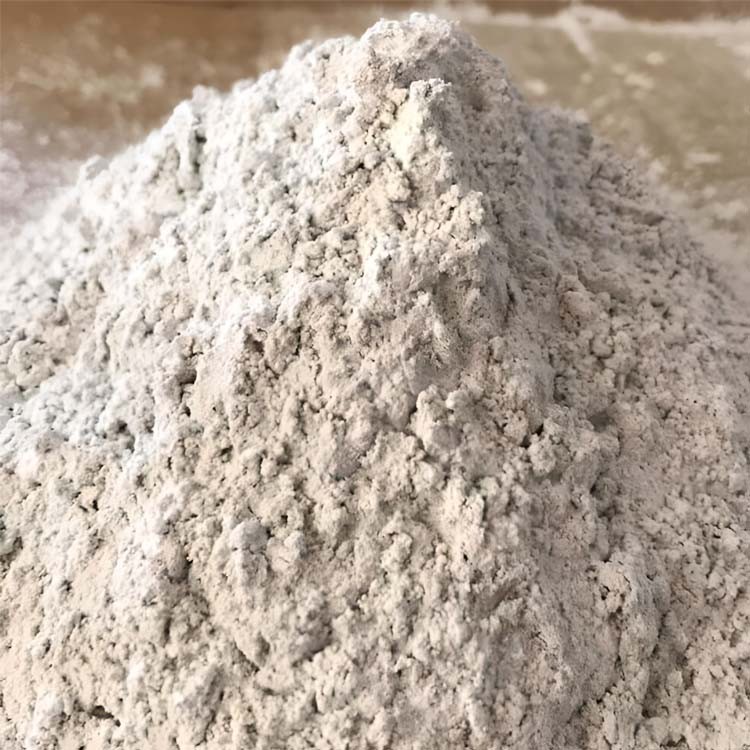

| Grade Ⅰ silica fume | SiO2 ≥88%, grey powder form, applied in high-strength non-shrinkage grouting materials. |

| Grade Ⅱ silica fume | SiO2 ≥85%, dark grey powder form, applied in high-strength commercial concrete. |

Package, Storage & Handling

1. Packed in woven fabric bag with plastic liner. Net weight:15kg /-0.13kg

2. It should be stored in a dedicated warehouse that is well-ventilated and dry. It remains effective for two years. At the expiration, re-use is allowed if the testing results fall within the established range. In case of humidity, re-use is allowed after drying and crushing.

Recommend

Now, let your business to a higher level, start professional consultation!

*We Will Reply To You Within 24 hours. Our working days are Mon.to Sat., 9:00 ~ 18:00.