GGBFS C Gr

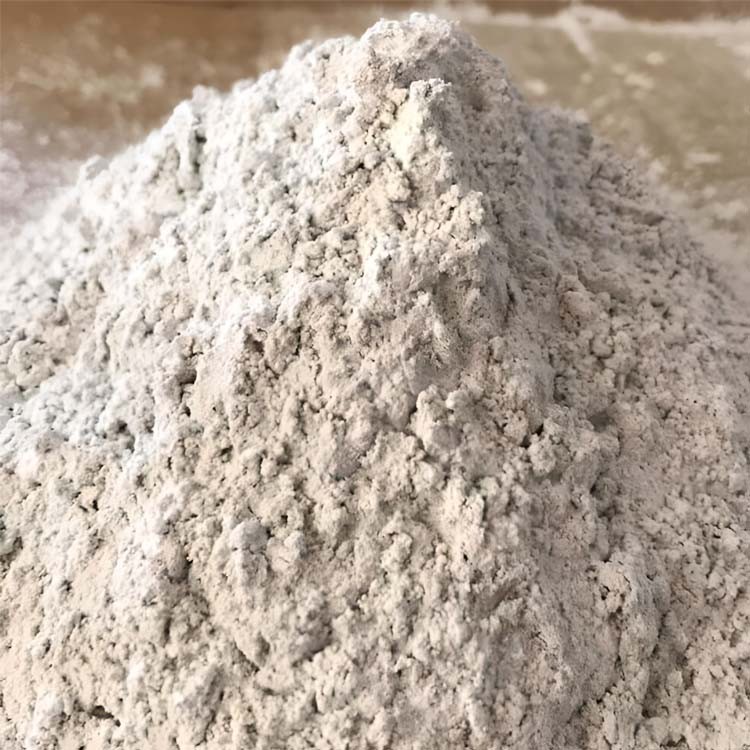

Ground Granulated Blast furnace Slag (GGBFS) is made by quenching molten blast furnace slag (a by product of iron and steel making) in water to produce a glassy granular product that is then dried and ground into a fine powder GGBFS. It consists mainly of calcium and aluminum silicates and has a chemical composition similar to these respective natural minerals and to hydrated Portland cement. GGBFS is typically finer than Type 1 Portland cement. It is an off-white color powder with a specific gravity of about 2.88 and is handled and dispersed like Portland cement.

- Fineness-blaine 420 (min.)

- Initial setting time 45 minutes (min.)

- le-chatelier expansion 10.00 mm (max.)

- Mortar compressive strength, 28 days 52.5 mpa

GGBFS B Gr

Ground Granulated Blast furnace Slag (GGBFS) is made by quenching molten blast furnace slag (a by product of iron and steel making) in water to produce a glassy granular product that is then dried and ground into a fine powder GGBFS. It consists mainly of calcium and aluminum silicates and has a chemical composition similar to these respective natural minerals and to hydrated Portland cement. GGBFS is typically finer than Type 1 Portland cement. It is an off-white color powder with a specific gravity of about 2.88 and is handled and dispersed like Portland cement.

- Fineness-blaine 420 (min.)

- Initial setting time 45 minutes (min.)

- le-chatelier expansion 10.00 mm (max.)

- Mortar compressive strength, 28 days 52.5 mpa

GGBFS A Gr

Ground Granulated Blast furnace Slag (GGBFS) is made by quenching molten blast furnace slag (a by product of iron and steel making) in water to produce a glassy granular product that is then dried and ground into a fine powder GGBFS. It consists mainly of calcium and aluminum silicates and has a chemical composition similar to these respective natural minerals and to hydrated Portland cement. GGBFS is typically finer than Type 1 Portland cement. It is an off-white color powder with a specific gravity of about 2.88 and is handled and dispersed like Portland cement.

- Fineness-blaine 420 (min.)

- Initial setting time 45 minutes (min.)

- le-chatelier expansion 10.00 mm (max.)

- Mortar compressive strength, 28 days 52.5 mpa

GGBS S95 std

What is GGBS ?

Ground Granulated Blast Furnace Slag(GGBS) from Fuzhou Golden Fortune Building Material is Cementitious material used to partially replace Ordinary Portland Cement (OPC) for various concrete, Masonary, Cement based product manufacturing and other purpose.

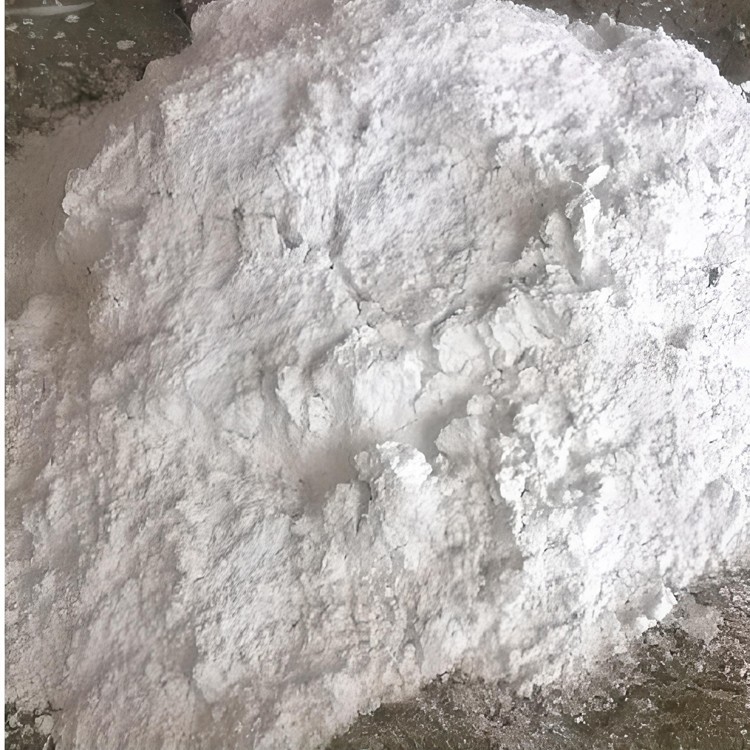

GGBS (Ground Granulated Blast-Furnace Slag) is an environmentally friendly product, made from a by-product of iron and steel making. This is a high quality, low CO₂ material,Although not technically a pozzolan, it behaves in the same way as popular pozzolans like PFA (Pulverised Fly/Fuel Ash). It is used as an alternative to PFA to strengthen and accelerate curing of non-hydraulic lime mortars. This material is a very fine white powder, indistinguishable from lime in appearance. Its light colour may make this material a better choice than PFA (Pulverised Fly/Fuel Ash) where a lighter colour or no change in colour is required.

GGBS S105 std

What is GGBS ?

Ground Granulated Blast Furnace Slag(GGBS) from Fuzhou Golden Fortune Building Material is Cementitious material used to partially replace Ordinary Portland Cement (OPC) for various concrete, Masonary, Cement based product manufacturing and other purpose.

GGBS (Ground Granulated Blast-Furnace Slag) is an environmentally friendly product, made from a by-product of iron and steel making. This is a high quality, low CO₂ material,Although not technically a pozzolan, it behaves in the same way as popular pozzolans like PFA (Pulverised Fly/Fuel Ash). It is used as an alternative to PFA to strengthen and accelerate curing of non-hydraulic lime mortars. This material is a very fine white powder, indistinguishable from lime in appearance. Its light colour may make this material a better choice than PFA (Pulverised Fly/Fuel Ash) where a lighter colour or no change in colour is required.

Concrete Admixture – Silica Fume

Description

Silica fume primarily consists of amorphous (non-crystalline) silicon dioxide. The average particle diameter is 0.08 um; specific surface area is about 4500 m2 /kg; and bulk density is 200 – 250kg/m3. Silica fume has extremely high surface activity with unformed spheroidal silica dioxide particle, the particle size is 1% of cement particle size. It will fill fully into the gaps among cement particles and create gel when reacts with hydrate compound. Golden Fortune dry densified silica fume powder designed to increase concrete compressive and flexural strength, reduce permeability, increase durability and improve hydraulic abrasion/erosion resistance.

- Advantage

- Reduces permeability

- Enhances durability against aggressive chemical attack

- Improved resistance to abrasion